Power Entry Module. PEM nut or self-clinching nut.

- What’s a PEM nut?

- What is a PEM in manufacturing?

- How do PEM nuts work?

- How do you insert a PEM stud?

- What is Pemsert?

- What is PEM in sheet metal?

- How do you press PEM nuts?

- Who owns PEM engineering?

- What are clinch nuts?

- What is PEM in mechanical engineering?

- What is PEM in engineering?

- How do you self clinch a nut?

- What does torque out mean?

- What is a self clinch stud?

- How do I install a captive pin?

- Post navigation

What’s a PEM nut?

PEM® Self-Clinching Nuts and Studs for Use in High-Strength Thin Steel Sheets Provide Permanent Threads for Automotive Component Attachment Applications. PEM SH nuts are engineered to install into high-strength steel sheets at 975MPa maximum ultimate tensile and as hard as HRC 30 or less on the Rockwell “C” scale.

What is a PEM in manufacturing?

PEM brand fasteners are hardware components that provide threaded attachment points for thin parts like sheet metal brackets and printed circuit boards (PCBs). The fastener (in this case a nut) has been pressed into a thin bracket. The bracket is attached to a mating part with a screw.

How do PEM nuts work?

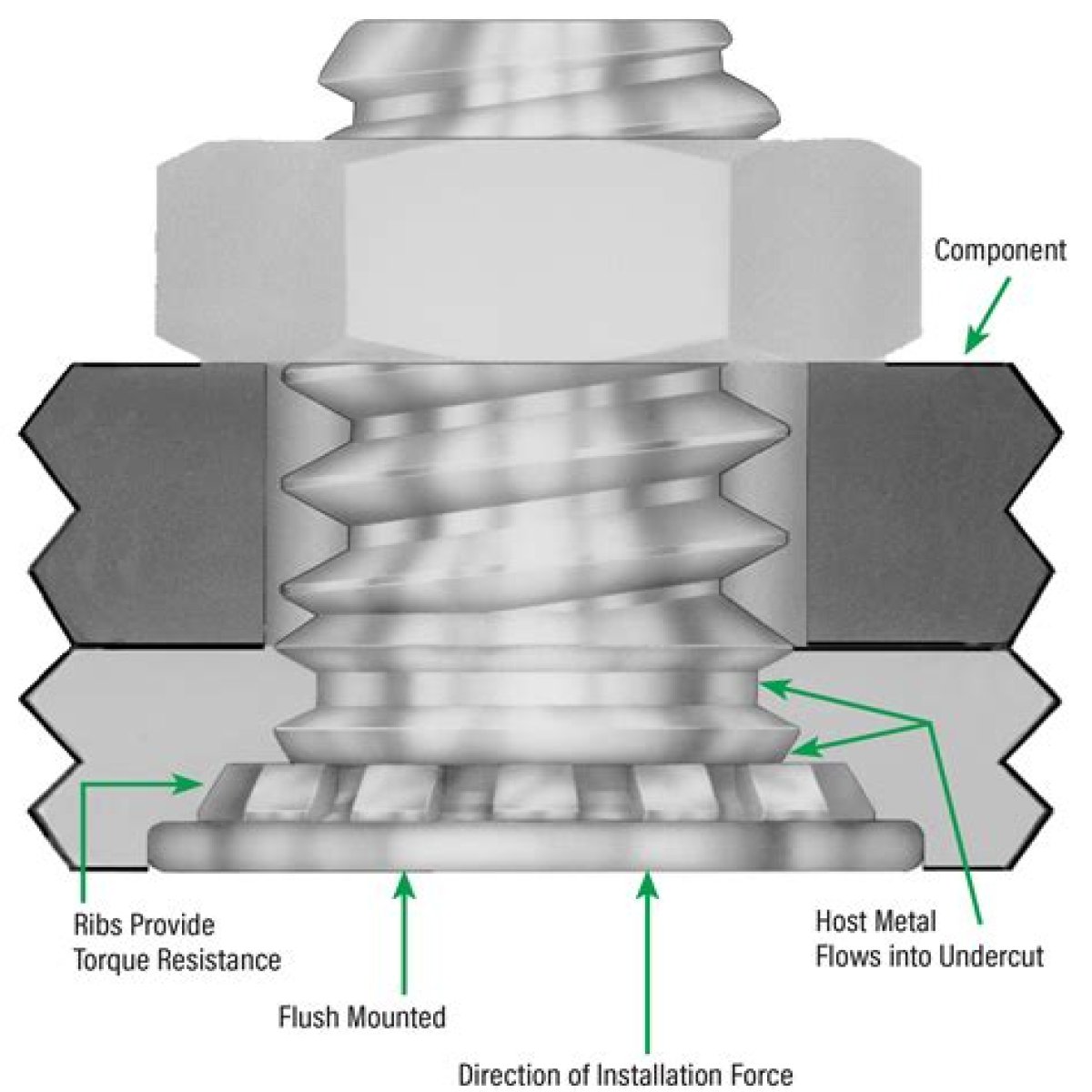

HB-4 PennEngineering • roadly defined, a self-clinching fastener is any device, usually threaded, that when pressed into ductile metal, displaces the host material around the mounting hole, causing it to cold flow into a specially designed annular recess in the shank or pilot of the fastener.

How do you insert a PEM stud?

PEM® self-clinching studs are easily installed by placing them in properly sized holes in sheets and squeezing into place with any standard press: Install permanently in aluminum, steel or stainless steel in sheets as thin as. 020” / 0.51 mm. High torque-out and pushout resistances.

What is Pemsert?

PEMSERTER machines from PennEngineering. PEMSERTER® presses are designed to safely, reliably, accurately and quickly install PEM fasteners. It is designed to install self-clinching fasteners in size M2 / #0 thru M10 / 3/8” in steel, and sizes up to M12 / 1/2” in aluminum panels or circuit boards.

What is PEM in sheet metal?

If you’re in the fabrication of sheet metal, you have probably heard the term “PEM® fastener”. PEM® brand fasteners, designed and manufactured by PennEngineering, utilize self-clinching technology for attaching to thin sheet metal.

How do you press PEM nuts?

PEM® Brand Fasteners Installation Demo

- Prepare properly sized mounting hole in sheet.

- Place shank of nut into mounting hole, preferably the punch side.

- With punch and anvil surfaces parallel, apply squeezing force until the head of the nut comes into contact with the sheet material.

Who owns PEM engineering?

PEM Holding, an affiliate of Tinicum Capital Partners, a private investment firm based in New York, will pay Penn Engineering shareholders $18.25 for each share held, Penn Engineering said.

What are clinch nuts?

Clinch nuts are self-clinching, internally threaded nuts that are pressed into the base material. Often times, these high strength fasteners are used in material that is too thin to tap threads. These fasteners oftentimes provide an immediate ROI for customers switching from weldnuts.

What is PEM in mechanical engineering?

The group Photons for Engineering and Manufacturing (PEM), formerly known as MSS (Materials Science and Simulations), performs research on structural and mechanical properties of metals and alloys with the aim to contribute to advanced manufacturing.

What is PEM in engineering?

PEM® brand fasteners utilize self-clinching, broaching, flaring, surface mount, or weld technology to provide strong, reusable, and permanent threads and mounting points in thin sheet metal, P.C. board materials, and other ductile or non-ductile thin material.

How do you self clinch a nut?

Make sure that the Shank or pilot of the fastener is located squarely in the hole before applying pressure. Apply a parallel squeezing force. Make sure the panel is held perpendicular to the Punch / Anvil. Apply enough force to totally embed the knurling so the shoulder of the nut is squarely in contact with the sheet.

What does torque out mean?

Torque-out reflects the torsional holding power of a fastener’s clinch feature, or the amount of torque necessary to spin the fastener out of the host metal sheet. This test often is made at the head of the fastener with values usually exceeding the ultimate torsional strength of a mating screw or nut.

What is a self clinch stud?

Self clinching captive studs are fasteners made from steel and plated with zinc, which are used for threaded stud attachments in thin sheet metal applications.

How do I install a captive pin?

To install a captive screw using a retaining flange, the flange is first pressed onto the panel. The captive screw is then screwed into the flange until the reduced diameter section is reached and the screw is retained.